|

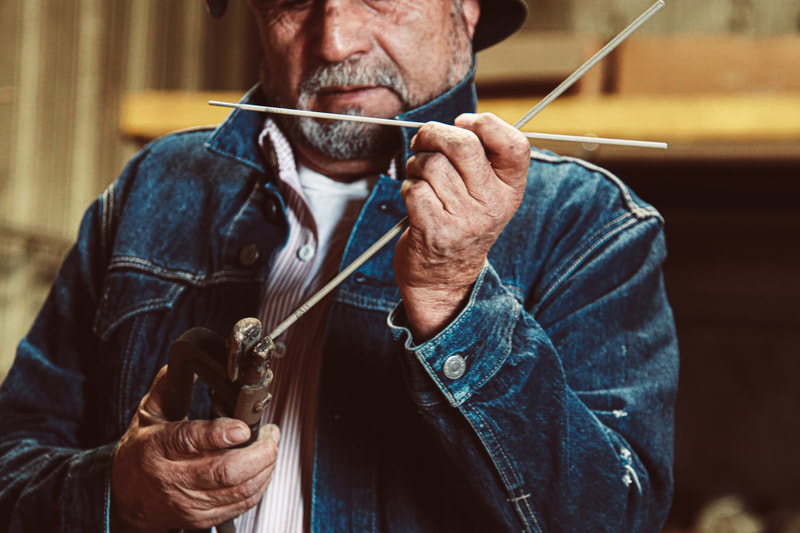

Things are likely to run smoothly when Bernardo Barbosa is on the job. Barbosa, who is in his 28th year at CRI Feeders, is respected among his peers and employer for his hard work, reliability and unique talent.

Barbosa’s day begins in the early morning hours. He checks with his maintenance crew to see what needs to be tended to — whether it be working in the mill, servicing tractors, fixing water leaks or repairing fences. Maintenance is never-ending at a feedyard as repairs and upkeep to infrastructure that houses thousands of feeder cattle is constant. What sets Barbosa apart is his sheer talent with a cutting torch and welder which, accordingly, is his favorite part about his job. “If I build something with my hands, I’m excited to show it to somebody when I get it done,” he laughs. “If it works.” One of Barbosa’s largest welding projects was building large, hydraulic squeegees for the feeyard’s tractors. The machines operate efficiently to help move snow from cattle pens. This equipment proves to be crucial for the feedyard during the winter months. The project was challenging, but Barbaso says, that’s one of the most enjoyable things about his work. “I like the challenge to do different things every day,” he says. “Doing different things keeps me motivated. And, at the feedyard, you put to practice what you learn from all the people that you have worked with.” He enjoys the people in the industry because they value what each employee brings to the table. “They respect what we do, and we all work together to get it done,” he says.

0 Comments

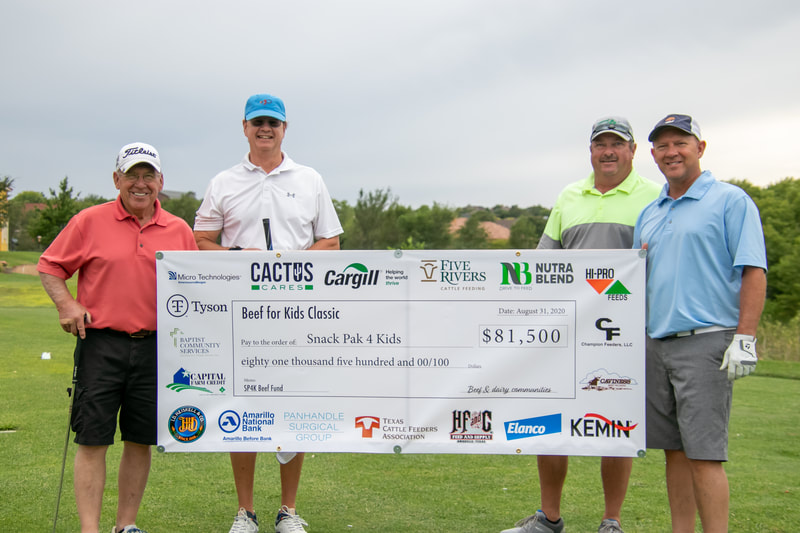

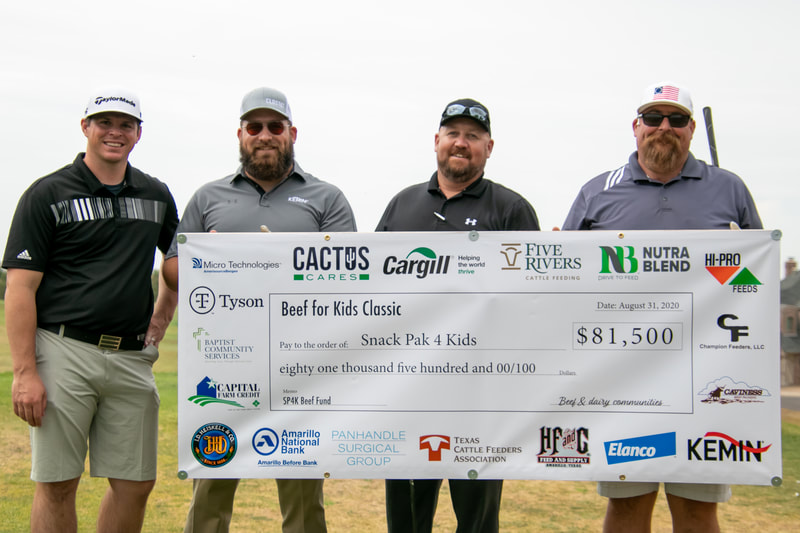

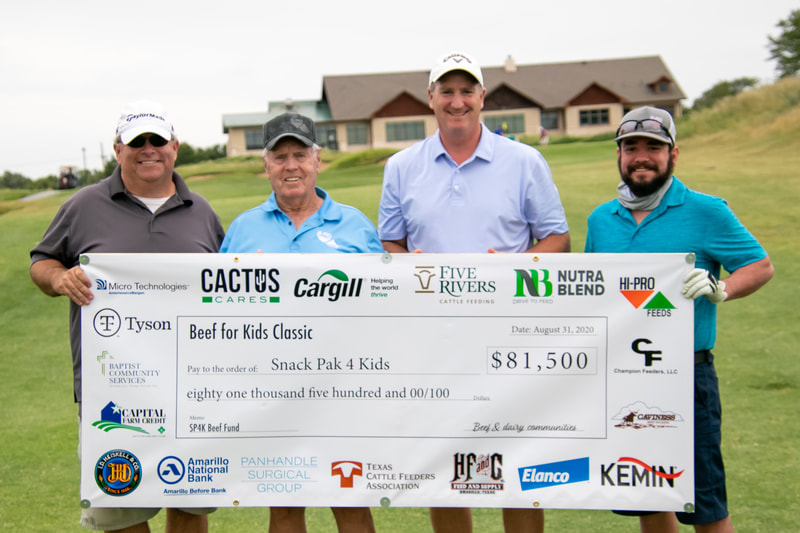

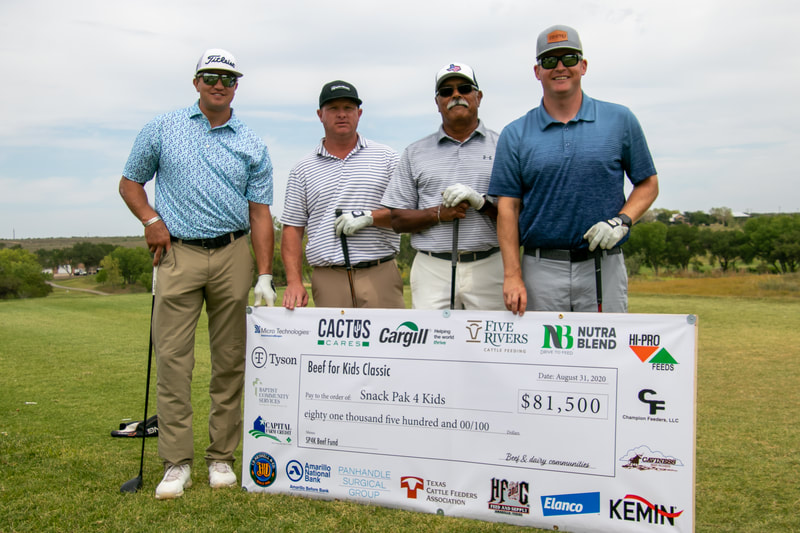

The Amarillo area beef and dairy communities presented a check for $81,500 to the Snack Pak 4 Kids (SP4K) Beef Stik Program. The money will provide beef sticks to hungry students through the Snack Pak weekend hunger program. The check was presented at the second annual Beef 4 Kids Classic golf tournament. "Our local agriculture community continues to step up to serve their communities," said Dyron Howell, SP4K founder. "This year we served 60% more kids due to the economic impact of COVID. We expect that trend to continue throughout the school year." The SP4K Beef Stik Program launched in October 2017. The program was designed to provide more protein for hungry students in the Texas Panhandle. “Ten percent of the sticks we need for the entire will be funded by this golf tournament,” Howell said. “When we first started, kids would get about 10-12 grams of protein in their bags each weekend, which is woefully inadequate. Today kids are getting 68 grams of protein in their bags. This is protein they desperately need to be successful both at home and school.” Beef provides ten essential nutrients and vitamins, including protein, zinc and iron – three key nutrients that are essential for proper growth and development of children. “TCFA is grateful for the strong partnership with Snack Pak and the opportunity it has provided the beef community to help provide high quality beef to students in our communities,” Wayne Craig, Cactus Cares executive director and chair of TCFA’s industry relations committee. “Cattle feeders have a commitment to serve our community, and it has been an honor to be a part of this partnership to reach out and help our neighbors.” How can you help:

TCFA would like to thank the sponsors and golfers who made this event possible. Major sponsoring organizations include Amarillo National Bank, Baptist Community Services, Cactus Cares, Capital Farm Credit, Cargill, Caviness Beef Packers, Champion Feeders, Elanco, Five Rivers Cattle Co., HF&C, Hi-Pro Feeds, JD Heiskell, Kemin Industries, Micro Technologies, Nutra Blend, Panhandle Surgical and Tyson Foods. Texas Cattle Feeders Association members are invited to join any of the following webinars, presented by the TCFA Finance and Taxation Committee. You can register here. If you have questions, please contact Josh Winegarner at [email protected] or Savanna Barksdale at [email protected]. Past Webinars Purchasing and Selling Cattle John Massouh, Attorney, Sprouse, Shadar, Smith PLLC David LeBas, Attorney, Naman, Howell, Smith & Lee PLLC Protecting Your Feedyard When Lending John Massouh, Attorney, Sprouse, Shadar, Smith PLLC David LeBas, Attorney, Naman, Howell, Smith & Lee PLLC Tax Relief Incentives

Mike Johanns, Chairman of Agriculture, alliantgroup and Former Secretary of Agriculture Tyler Noesser, Technical Director, alliantgroup

By: Carmen Fenton, Director of Communications

No two days are ever the same for Armondo De La Cruz. He has learned to expect the unexpected. “If a truck breaks down, everything stops,” he says. The feedyard depends on De La Cruz to keep machinery and vehicles operating. He has worked at the feedyard for 35 years doing a number of jobs from throwing hay, batching and loading, to calling feed. But he thrives in work that requires meticulous and steady hands. “We run the shop department,” he says. “We do the maintenance on the trucks, brakes, water pumps, anything that we need to do. The feed trucks, the corn haulers and the vehicles here in the yard.” His dad, a mechanic by trade, moved his family from Laredo to Hereford when De La Cruz was a young boy. It was his dad who gave De La Cruz his first lesson in mechanics. That is something he has passed on to both of his sons. “My dad was a mechanic, and that’s where I learned,” Cruz says. “And I got my younger son here now, and he’s learning. And my older son, he also worked here with me.” Hereford is home for De La Cruz and his family. He and his wife raised three children (two sons and a daughter) in the area. Now, they have grandkids, which De La Cruz says is “awesome” since you can sugar them up and send them back to their parents. When asked what advice he would give to a young man or woman wanting to get into the mechanical field, he smiles and says, “Just love what you do, and the rest will take care of itself.” It is clear that advice helped Cruz along the way. “I mean it sounds corny,” he says. “But if you like it, that’s good. And then if you can crack a smile on your face every day, it’s probably better stuff.”

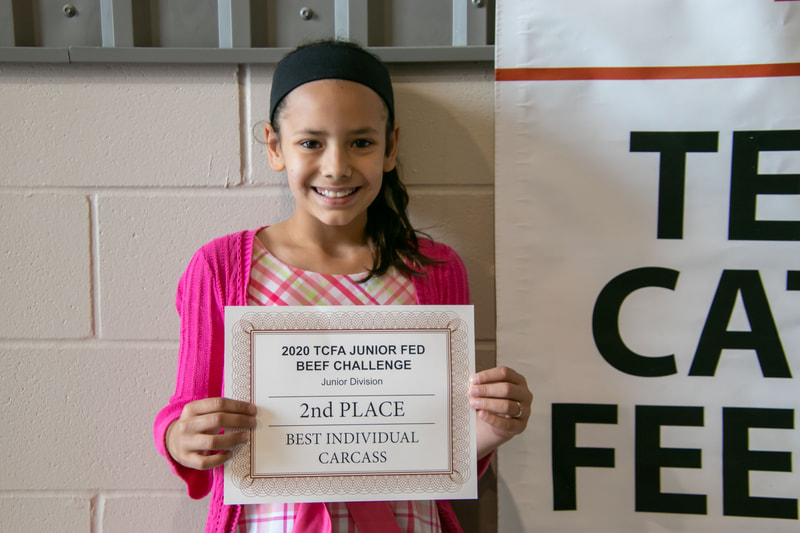

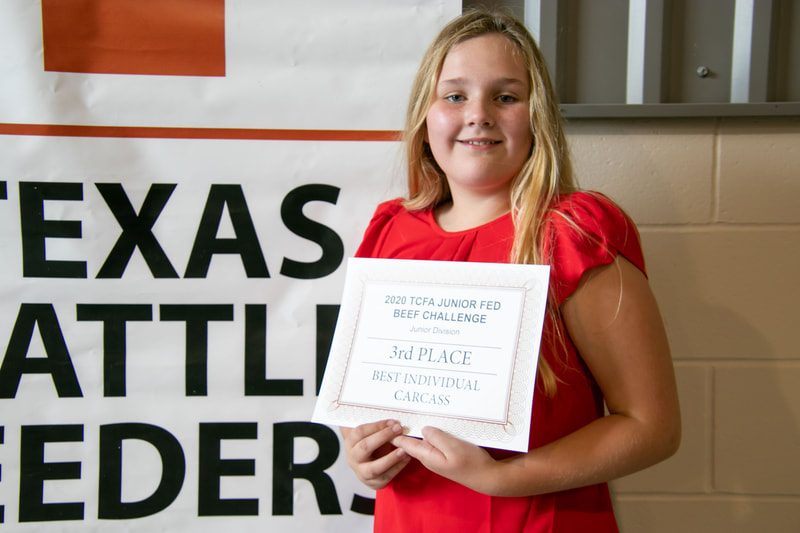

Students from across the state made their way to the campus of West Texas A&M University on Friday, July 24, to showcase their skills and knowledge at the 2020 TCFA Junior Fed Beef Challenge.

This annual contest gives third-12th grade students the opportunity to gain industry knowledge and practical experience in commercial cattle feeding. Students feed a pen of three steers, take a written test and compete in interviews and oral presentations. Cattle performance points are also figured into the score to determine the winners. Students compete for a combined $20,000 in college scholarships along with trophy buckles and plaques.

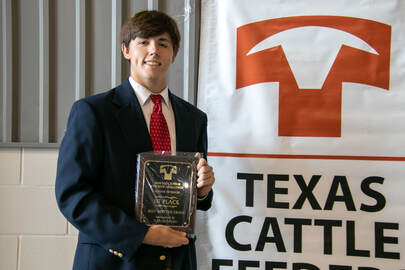

The Senior Overall Champion of the contest and winner of a $5,000 scholarship was Luke Bludau of Hallettsville. Senior Reserve Champion and winner of a $3,000 scholarship was Macy Lawrence of Canyon. The First Runner-Up and winner of a $2,000 scholarship was Grant Kubala of Schulenburg.

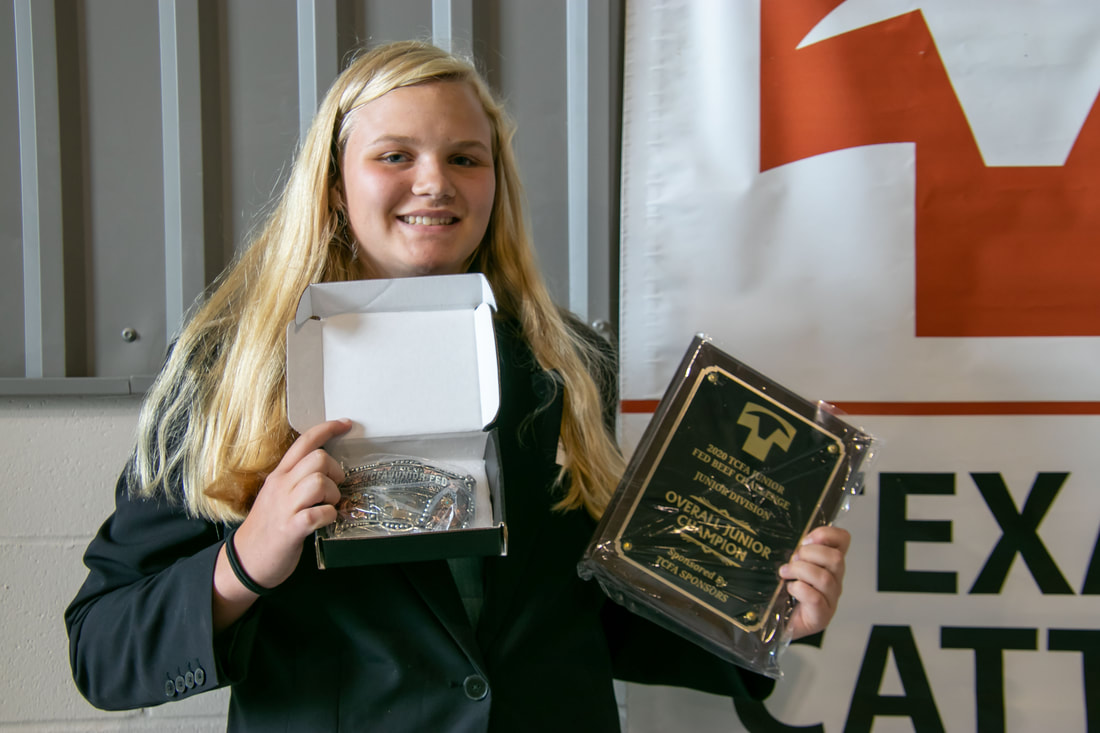

In the Junior Division, Emma Stevenson of Earth was named the Overall Champion and received a $350 scholarship.

Senior Division: Best Written Exam

3rd Place Written Exam – Macy Lawrence, Canyon 2nd Place Written Exam – Gavin Kubala, Schulenburg; Grant Kubala, Schulenburg 1st Place Exam and winner of a $500 prize – Luke Bludau, Hallettsville

Senior Division: Best Interview

3rd Place Interview – Hayden Holwick, McLean ; Kade Lawrence, Canyon 2nd Place Interview – AnneMarie Metzler, Cotton Center Best Interview and winner of a $500 prize – Macy Lawrence, Canyon

Senior Division: Best Individual Carcass

3rd Place Individual Carcass – AnneMarie Metzler, Cotton Center; Clayton Stevenson, Earth 2nd Place Individual Carcass – Shelby Berckenhoff, Hallettsville; Brayden Smith, Blair Top Individual Carcass and winner of a $500 prize – Clayton Stevenson, Earth

Senior Division: Best Pen Steer Points

3rd Place Carcass Pen – James Golla, College Station; Lane Golla, New Braunfels 2nd Place Carcass Pen – Clayton Stevenson, Earth Top Carcass Pen and winner of a $500 prize – Brayden Smith, Blair

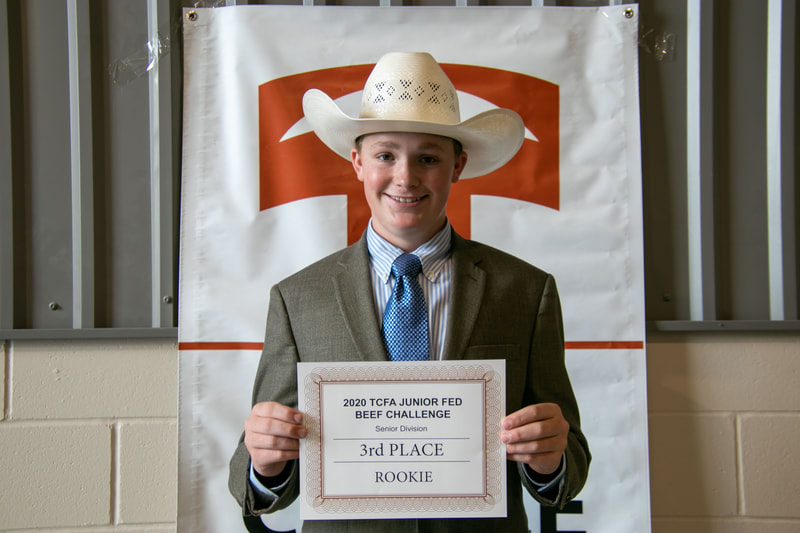

Senior Division: Top Rookie Award

3rd Place Rookie – Jett Long, Yoakum 2nd Place Rookie – Hayden Holwick, McLean Top Rookie and winner of a $500 prize – Brayden Smith, Blair

Junior Division: Best Written Exam

3rd Place Written Exam – Alexandra Kelley, New Braunfels 2nd Place Written Exam – Kaydence Hood, Stratford 1st Place Exam and winner of a $250 prize – Jake Ressler, Hallettsville; Emma Stevenson, Earth

Junior Division: Best Presentation

3rd Place Presentation – Jenna Stevenson, Earth 2nd Place Presentation – Levi Golla, New Braunfels; Kaydence Hood, Stratford; Alexandra Kelley, New Braunfels Best Presentation and winner of a $250 prize – Emma Stevenson, Earth

Junior Division: Best Individual Carcass

3rd Place Individual Carcass – Jenna Stevenson, Earth 2nd Place Individual Carcass – Landon Koehne, Hallettsville; Abby Ressler, Hallettsville; Walton Marshall, Midland; Virginia Stevenson, Bushland Top Individual Carcass and winner of a $250 prize – Levi Golla, New Braunfels; Lexi Golla, New Braufels; Luke Golla, New Braunfels; Jenna Stevenson, Earth

Junior Division: Best Pen Steer Points

3rd Place Carcass Pen – Alexandra Kelley, New Braunfels 2nd Place Carcass Pen – Jenna Stevenson, Earth Top Carcass Pen and winner of a $250 prize – Levi Golla, New Braunfels; Lexi Golla, New Braunfels; Luke Golla, New Braunfels

Junior Division: Top Rookie Award

2nd Place Rookie – Landon Koehne, Hallettsville Top Rookie and winner of a $250 prize – Kaydence Hood, Stratford

Suzy Hicks and Cindy Shipp can be best described as a dynamic duo. The pair has worked together for almost 20 years at Dawn Custom Cattle Feeders.

Hicks, office manager, began working at the feedyard when it opened its doors. She’s often the first person to greet customers when they walk through the front door. She also keeps track of every transaction made at the feedyard. “Whatever they do today, I'll put in my computer tomorrow,” Hicks says. “Medicine, feed, anything pertaining to the cattle, I keep track of it.” In an office three feet from Hick’s front desk, Shipp, controller, manages the feedyard’s financials. Everything from payroll to receivables. “No day is the same in a feedyard,” Shipp says. “It's all different. It’s a new world every day.” Suzy and Cindy attribute their loyalty to the people they work with. “We've got a great crew who gets along really well,” Hicks says, “which makes it easy to come to work every day.” Shipp says there is an understanding amongst the employees that everyone gets to work and does their job. “We all know our jobs here,” Shipp says. “You work hard, get it done, and people show you respect.” When asked what they like most about their jobs, both are quick to acknowledge one another and their ability to work well together. “You know, I can tell when Cindy's got a lot on her plate,” Hicks says. “We both know when to let each other work, but we also know when to chat and have a cup of coffee.” Both women exhibit gracious cooperation and hard work, two characteristics necessary for success at a feedyard.

For cattle on a feedyard, perhaps few things are as important as a steady mill operation.

It’s 5:30 a.m. when Manuel Joven arrives at the feedyard and makes his way to the feed mill. His crew is running rolls, prepping boilers and flaking corn for the day’s feed. For the more than 50,000 head of cattle that call the feedyard home, perhaps few things are as important as a steady mill operation.

A calm, laid-back morning is a sign the day is off to a good start, and as Joven puts it, “The mill should be very consistent. You want to predict what time you will make your first round of feed, second round, third round and special rations. You want to predict what time you will be done at the end of the day.” For Joven, managing the feed mill is the culmination of years of learning. Born in Mexico, he moved to Texas when he was nine years old and worked summers in the feedyard while in high school. His dad, brother, uncle and cousin all work alongside him, and Joven credits each of them for teaching him the ropes. “My dad operates the loader, so that’s how I got my background with the loader,” he says. “I’ve got an uncle that works in the mill with me, so I picked up a bunch on gear boxes, motors, belts, drags, chains — everything that goes on in the mill, I learned from him.” Similarly, his brother drives a feed truck and his cousin is the head doctor. “They know how to do the work,” Joven says. “I learned that from them. Now I know how to do the work as well.” Every morning, Joven climbs to the top of the mill and observes the yard. From there he can see if everything is running smoothly, take note of where the feed trucks are and where cattle are moving. It’s up top where Joven listens to the mill. “A bearing could start making a different noise. An auger may be rubbing against a trough,” he says. “You may just go up there, enjoy the breeze and come back down and all is good. But you stop doing that, there’s going to be one day that you could’ve prevented something.” Joven loves what he does and the industry he works in. He says the more time you spend paying attention to details, the quicker you respond to challenges before they become problems. “Little things you start looking at, like inspection doors, the bearings, the motors, the gear boxes,” he says. “Just touch them. If they’re getting hot, it is probably because they’re not lubed correctly.” Joven has had a steady mill crew for five years, a milestone he is proud of considering that long hours and manual labor can lead to high turnover. Keeping his crew around for the long haul keeps for calmer, more consistent days. “It’s tough. It’s not easy. You just got to have a passion for it,” Joven says. “But keep the guys safe, keep the guys motivated and it turns out to be pretty good.”

Carmen Fenton is the communications director for the Texas Cattle Feeders Association. She's also mom to Ella Jane (9), Hays (8) and Lane (2).

The Coronavirus Food Assistance Program (CFAP) will aid agricultural producers impacted by the effects of the COVID-19 outbreak. On May 19, 2020, USDA published a rule that specifies the eligibility requirements, payment calculations and application procedures for CFAP. The program will be administered by the USDA-Farm Service Agency (FSA). To help inform you of the program requirements and application process, we created a short webinar outlining the three-step process. We've also outlined the steps below, and a printable version can be downloaded here. STEP #1 – Locate your local FSA service center USDA service centers are open for business by phone appointment only. FSA is also working with producers by phone, email, mail and fax. STEP #2 – Submit completed forms to FSA

Complete the forms below and submit them to your local service center. If you are already established with FSA, it is likely many of these forms are already on file at your local FSA service center. However, if your average AGI for the previous three years is more than $900,000, Form CCC-942 must be signed by your CPA or attorney to verify that 75% of your income is from agriculture.

The following is a status update on TCFA events in light of concerns surrounding COVID-19. Please know that the health and safety of participants is our number one priority. This list is subject to change as we learn more. Canceled TCFA Fed Beef Challenge - Originally scheduled for April 8 TCFA Feedyard Tech, Spring Semester - Originally scheduled for April 14-16 and 21-23 TCFA Spring Safety Seminar TCFA Feedyard Camp - Originally scheduled for June 23-26 On Schedule TCFA Junior Fed Beef Challenge - Contest day July 24 TCFA Convention - October 4-10, Grapevine, Texas

Ongoing efforts to keep you informed on news surrounding the beef industry and COVID-19.

May 13, 2020

|

Categories

All

Archives

June 2024

|

About TCFA |

Get Involved |

|